LanammeUCR has highly qualified technical staff and modern laboratories equipped to perform multiple and complex tests. Its quality management system is based on the INTE-ISO/IEC-17025:2017 standard and currently has around 100 tests and two calibration methods accredited by the Ente Costarricense de Acreditación (ECA) under this standard.

The general objective of the laboratories is to support research in construction materials, construction systems and metrology, at a national level, by carrying out laboratory tests and calibrations for quality verification, innovation, and development.

The specific objectives are: to offer routine, special and verification tests, and calibrations to public and private institutions; give support to courses and research projects in undergraduate, graduate and LanammeUCR’s own; train the interested population in the execution of laboratory tests, technical standards related to construction materials, construction systems, metrology and various topics related to the work of LanammeUCR; participate in the development of national technical regulations; disseminate relevant results of national interest through the publication of technical articles in magazines, publications on LanammeUCR’s website and social networks; support LanammeUCR’s programs in various activities that require laboratory services.

The laboratories are divided into three areas: construction, transportation and pavements y metrology.

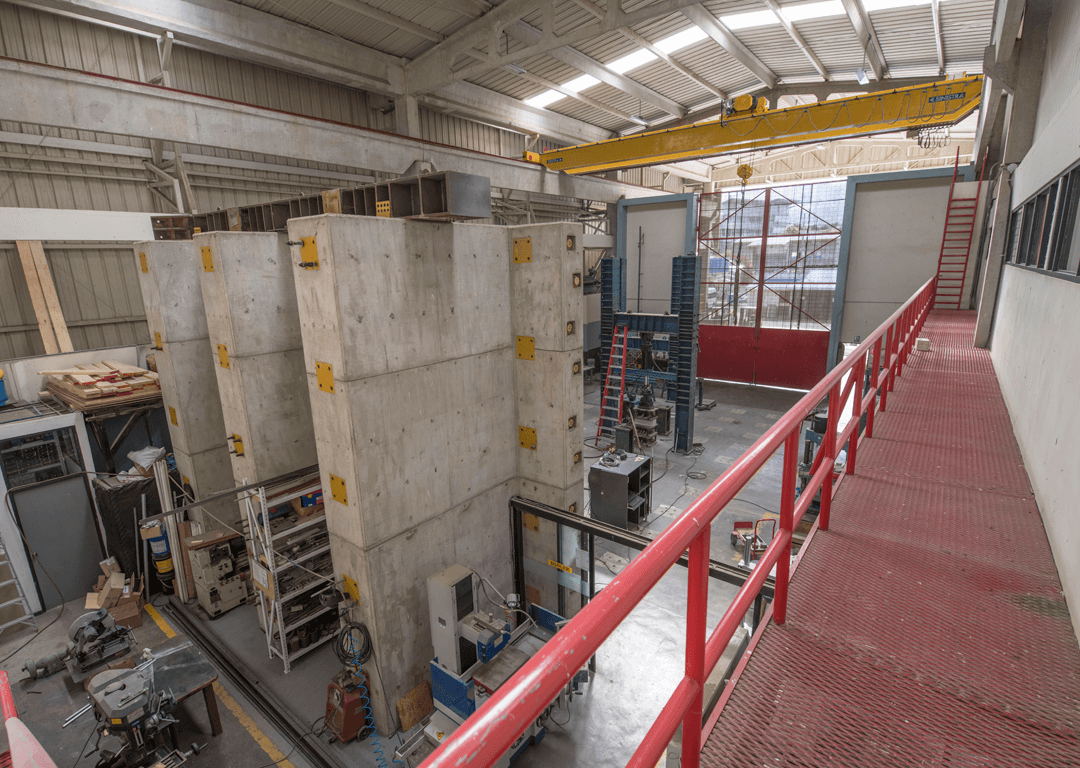

In the construction area, tests are carried out that allow the physical-mechanical characterization of aggregates, cement, concrete, mortar, masonry, construction rods, and steel. The physical-mechanical properties of soils and rocks are determined and the behavior of various materials such as metals, wood, polymers, and plastics, among others, are studied. These laboratories have a reaction wall and floor where building systems and houses of up to two levels are tested on a natural and reduced scale. Elements and components of concrete, masonry and steel are also tested. Additionally, field tests are carried out such as sampling of materials such as aggregates, soils, concrete, soil infiltration and the quality of the materials of existing reinforced concrete or masonry structures are determined. These laboratories have high-tech equipment, such as servo-controlled universal machines with dynamic capacity, servo-controlled actuators, automated triaxial machines, among others.

Transportation and pavements area

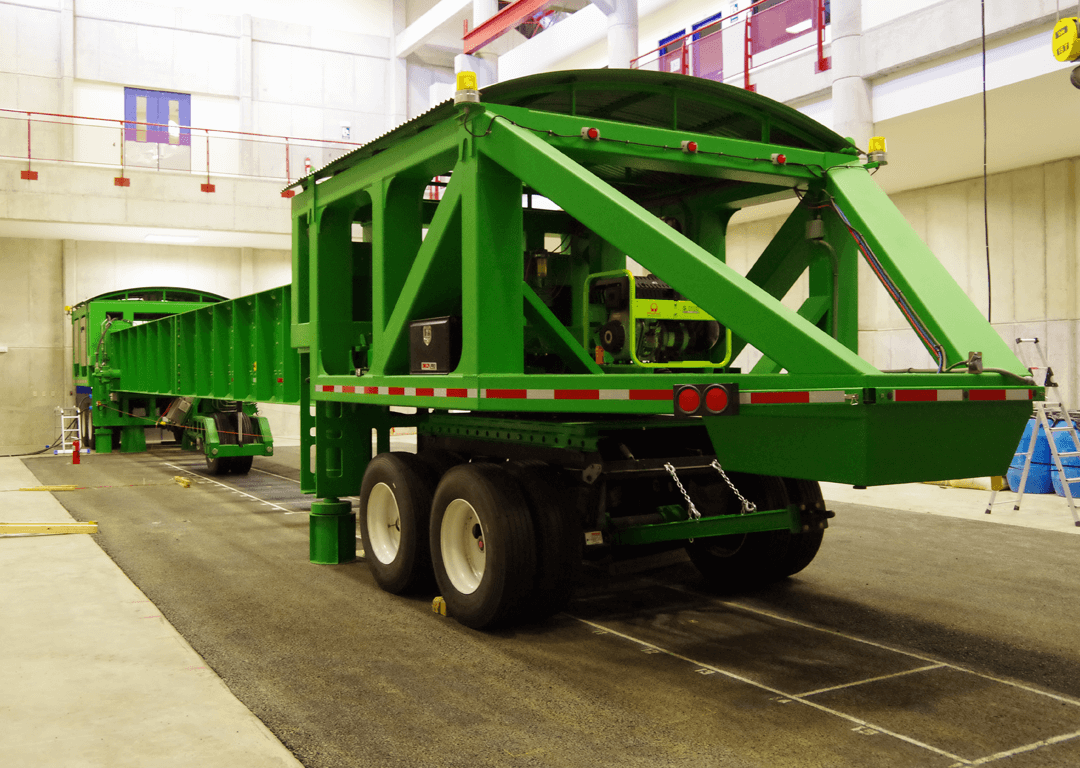

In the transportation and pavements area, there are equipment for the physical-mechanical characterization of materials, such as binders, slurries and asphalt mixes, granular and stabilized bases, and subgrades. The works cover both analyses using conventional equipment, as well as specialized equipment for its design and characterization. Among these, high-precision dynamic equipment stands out for the evaluation of mechanical properties of soils, granular and asphalt materials; dynamic rheometers (DSR) for the characterization of asphalt binders; and equipment for the design of asphalt mixtures using the Superpave® methodology, including a whole range of equipment for the evaluation of its performance in terms of fatigue, permanent deformation and moisture damage. Additionally, there is high-performance equipment for the auscultation-evaluation of the structural and functional performance of pavements for highways and airports, such as impact deflectometers: light-standard and heavy (FWD); laser profilometers (RSP) for evaluation of regularity, rutting and macrotexture; friction evaluation (Grip tester) and photographic evaluation for paving auscultation (Imajbox). It also has the equipment to test pavements on a full scale with simulation of climatic conditions such as temperature or saturation of the layers with the action of the traffic with the Heavy Vehicle Simulator (HVS).

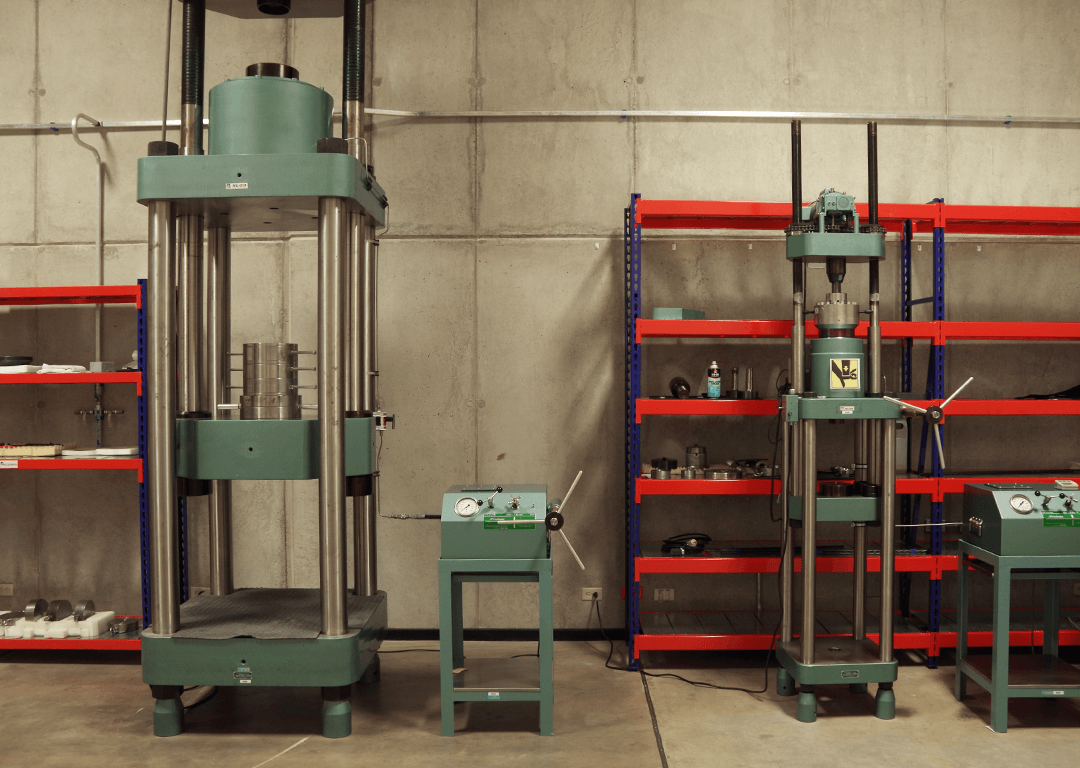

The laboratories are also supported by a metrological facility, which is in charge of calibrating force measuring machines and instruments. This laboratory, through an agreement with LCM (Costa Rican Metrological Laboratory), is designated as the national reference laboratory for force magnitude and is the custodian of the national force standards, with measuring capacity from 10 N to 3000 kN.